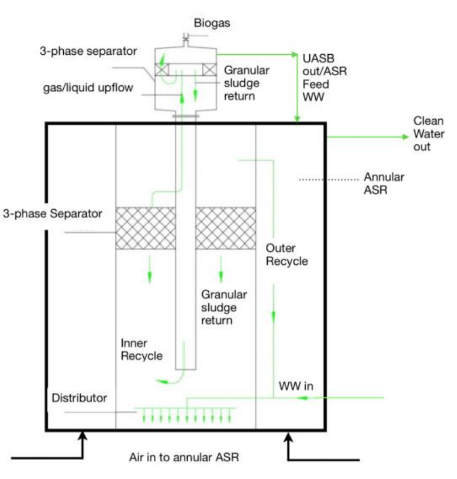

High organic content wastewater can be treated in a compact system with high motion rates as result. This novel technology uses a self contained up-flow anaerobic sludge blanket reactor integrated to an activated sludge system. Both reactors, anaerobic and aerobic, are incorporated into a single compact unit, in the form of two concentric cylindrical vessels. The internal vessel houses the anaerobic reactor, and the external annular space comprises the aerobic stage. This results in a very compact design with minimal footprint. The anaerobic reactor is further fitted with internal baffles that compartmentalize the interior to simulate several reactors operating in parallel, as well as providing for the internal recycling of granular sludge within the reactor to accelerate return of a fraction of the suspended granules to the bottom of the reactor.

Anaerobic reactor [acidogenesis+methanogenesis+

denitrification], followed by activated sludge process with recycle [polishing+nitrificaction]

The re-circulation from the SPRAS system to the anaerobic reactor improves denitrification.

Increased flow velocity, increases mass transfer rate.

Bio-gas capture system that would allow for energy recovery, current systems produce roughly 1.75 m3 of bio-gas per m3 of water processed.

No capital expense for the customer, which allows faster decisions and implementation.

© 2022 All Right Reserved. Designed By AKNY Media.